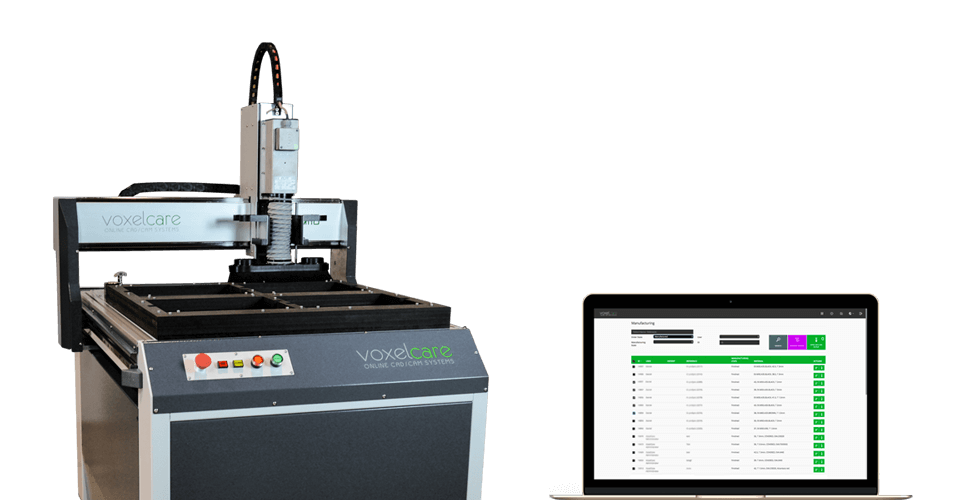

VCM110

Voxelcare Production

The VCM110 orthotic milling machine is the latest milling machine development of Voxelcare. It is the new version of the successful VCM100 milling machine. When it comes to productivity, the innovative VCM110 is in a class above all other insole milling machines.

Overview

Greater productivity

The VCM110 orthotic milling machine is the latest milling machine development of Voxelcare. It is the new version of the successful VCM100 milling machine. When it comes to productivity, the innovative VCM110 is in a class above all other insole milling machines.

Latest insole milling technology

The VCM110 is fitted with the latest insole milling technology to meet the needs of a production environment. A high-end insole milling machine model with the most advanced machine components that assures performance as well as accuracy.

Customizable

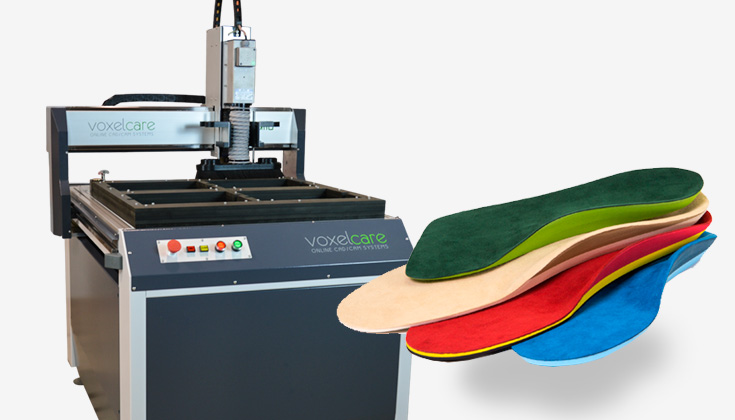

Standard configured as a 4-pair slots machine, the machine can also be customized. The machine will then have more milling slots available for you to mill larger batches.

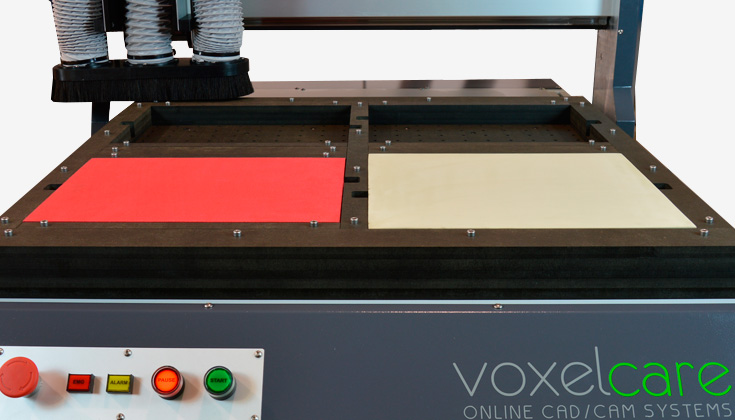

Intelligent 2-Sided milling

Mill with the highest possible speed your orthotics products with the tailed milling strategies. Mill the orthotic products on 2-sides to save you time, money and give you the highest quality.

Advantages

2-Side milling

Mill insoles on 2-sides (top and bottom side), save a lot of time in manual grinding and finishing

Mill 4 pairs

Mill 4 pairs per batch from slots or mill directly out of plate material

High Quality

Suited for milling EVA orthotics Very robust aluminum frame, including vacuum table

High performance engine

Brushless milling motor 2.2 Kw, 6000 – 24000 rpm

High speed

12 meters/min

Reliable

Linear guides with recirculating self-lubricating bearings, tight and without gaps

Versatile and powerful

Transmissions in all axes of spindles, with screwball recirculating and stepping motors engines with encoder and 90 Kg/cm of torque per motor

Features

Dimensions

1090 x 1230 x 1460 mm

Working area

780 x 640 x 65 mm (Z axis height)

Weight

390 kg

Milling time

Up to 10 min/pair (two sides)

Accuracy

0.01 mm

Power

380V three-phase

Required operating system

Windows 7 OS or a later version